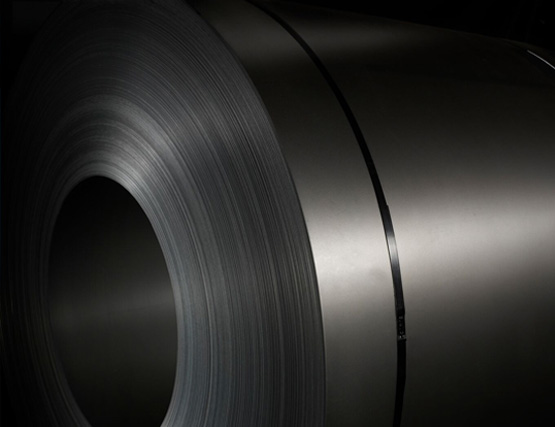

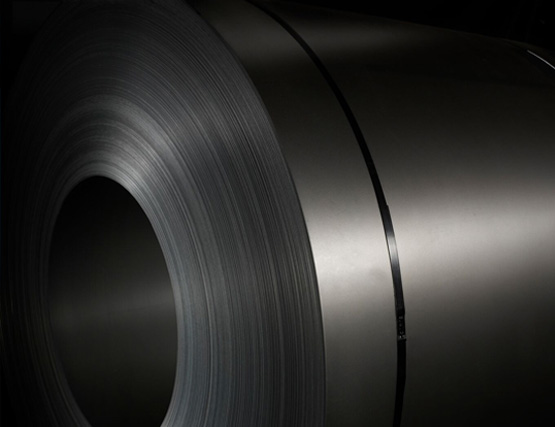

Cold Rolled Coils (CRCA and CR Full Hard)

CRCA – Cold Rolled Closed Annealed

Cold-rolled coils are a type of steel product that undergoes a specific manufacturing process known as cold rolling. Unlike hot-rolled coils, which are produced at high temperatures, cold-rolled coils are manufactured at room temperature or slightly below. This process involves passing the steel through a series of rollers, which gradually reduce its thickness and improve its surface finish.

CRFH (Cold Rolled Full Hard)

CRFH (Cold Rolled Full Hard) coils, on the other hand, are cold-rolled steel coils that do not undergo the annealing process. After cold rolling, they are typically subjected to a final cold reduction process to achieve the desired thickness and mechanical properties. CRFH coils are cold-rolled to their maximum hardness and strength, resulting in a harder and stiffer material compared to CRCA coils. They have a more rigid structure and exhibit higher yield strength and resistance to deformation.

Basic Parameters

| Classification | EN |

|---|---|

| Head | Body |

| Width | 4.5 mm to 1850 mm |

| Length (For Sheets) |

As Per Customer's Requirement |

| Grades | CR1, CR2, CR3, CR4, CR5, HSLA, Dual Phase |

| Finish | Bright, Semi-Bright, Normal, Rough |

| Classification | EN | JIS | ASTM | BIS | JFS |

|---|---|---|---|---|---|

| CQ | DC01 | SPCC | CS A,B & C | CR1 | - |

| DQ | DC03 | SPCD | DS A & B | CR2 | JSC270C |

| DDQ | DC04 | SPCE | - | CR3 | JSC270D |

| EDDQ | DC05 | SPCF | DDS | CR4 | JSC270E |

| IF | DC06 | SPCG | EDDS | CR5 | JSC270F |

| High Strength - IF Based | HC180Y | - | SHS-GR35 | CR5_IF340 | JSC340P |

| HC220Y | - | - | - | - | |

| HC260Y | - | SHS-GR44 | CR5_IF390 | JSC390P | |

| - | - | - | CR5_IF440 | JSC440P | |

| Bake Hardened | HC180B | - | BHS-GR26 | - | - |

| HC220B | - | BHS-GR35 | - | JSC340H | |

| HC260B | - | - | - | - | |

| HC300B | - | BHS-GR44 | - | - | |

| High Strength Micro Alloyed Steel |

HC260LA | - | - | - | - |

| HC300LA | - | - | - | - | |

| HC340LA | - | HSLAS-GR50 | - | - | |

| HC380LA | - | HSLAS-GR55 | - | - | |

| HC420LA | - | HSLAS-GR60 | - | - | |

| C-Mn High Strength Steel | - | SPFC340 | SS GR48 | CR1_340 | JSC340W |

| - | SPFC390 | - | CR1_390 | JSC390W | |

| - | SPFC440 | SS GR65 | CR1_440 | JSC440W | |

| - | SPFC490 | SS GR60 | - | - | |

| Rephosphorized | HC180P | - | - | - | - |

| HC220P | - | - | - | - | |

| HC260P | - | - | - | - | |

| - | - | - | - | JSC440R | |

| - | - | - | - | JSC590R | |

| Dual Phase | HCT500X | - | - | - | - |

| HCT600X | - | - | - | JSC590Y | |

| HCT780X | - | - | - | JSC780Y | |

| - | - | - | - | JSC980Y | |

| HCT980X | - | - | - | JSC980YL |

| Ref STD | MechanicalProperties | Chemical Properties | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steel Type | Ref STD | UTS | Y.S(N/mm2) | % EI | n90 | r90 | C% | Mn °/0 | Si % | AI % | S% | P% | Ti% | Nb% | |

| (N/mm2) | (Max) | (Max) | (Max) | (Max) | (Max) | (Max) | |||||||||

| Min | Min | Max | Min | Min | Min | ||||||||||

| CQ | EN_DC01 | 270 | 140 | 280 | 28 | - | 0.12 | 0.6 | - | - | 0.045 | 0.045 | - | ||

| DQ | EN_DCO3 | 270 | 140 | 240 | 34 | - | 1.3 | 0.1 | 0.45 | - | - | 0.035 | 0.035 | - | - |

| DDQ | EN_DC04 | 270 | 140 | 210 | 38 | 0.18 | 1.6 | 0.08 | 0.4 | - | - | 0.03 | 0.03 | - | - |

| EDDQ | EN_DCO5 | 270 | 140 | 180 | 40 | 0.2 | 1.9 | 0.06 | 0.4 | - | - | 0.025 | 0.025 | - | - |

| IF | EN_DC06 | 270 | 120 | 180 | 38 | -0.22 | -1.8 | 0.02 | 0.35 | - | - | 0.02 | 0.02 | 0.03 | - |

| High Strength - IF based | EN_HC180Y | 340 | 180 | 230 | 36 | 0.19 | 1.7 | 0.01 | 0.7 | 0.3 | - | 0.025 | 0.06 | 0.12 | - |

| EN_HC220Y | 350 | 220 | 270 | 34 | 0.18 | 1.6 | 0.01 | 0.9 | 0.3 | - | 0.025 | 0.08 | 0.12 | - | |

| EN_HC260Y | 390 | 260 | 320 | 32 | 0.17 | 1.4 | 0.01 | 1.6 | 0.3 | - | 0.025 | 0.1 | 0.12 | - | |

| Bake Hardened | EN_HC180B | 300 | 180 | 230 | 34 | 0.17 | 1.6 | 0.05 | 0.7 | 0.5 | - | 0.025 | 0.6 | - | - |

| EN_HC220 | 320 | 220 | 270 | 32 | 0.16 | 1.5 | 0.06 | 0.7 | 0.5 | - | 0.025 | 0.08 | - | - | |

| EN_HC260B | 360 | 260 | 320 | 29 | - | - | 0.08 | 0.7 | 0.5 | - | 0.025 | 0.1 | - | - | |

| EN_HC300B | 400 | 300 | 360 | 26 | - | - | 0.1 | 0.7 | 0.5 | - | 0.025 | 0.12 | - | - | |

| HIGH STRENGTH/MICRO ALLOYED STEEL | EN_HC260LA | 350 | 260 | 330 | 26 | - | - | 0.1 | 0.61 | 0.05 | - | 0.025 | 0.025 | 0.15 | 0.09 |

| EN-HC300LA | 380 | 300 | 380 | 23 | - | - | 0.1 | 1.1 | 0.05 | - | 0.025 | 0.025 | 0.15 | 0.09 | |

| EN_HC340LA | 410 | 340 | 420 | 21 | - | - | 0.1 | 1.6 | 0.05 | - | 0.025 | 0.025 | 0.15 | 0.09 | |

| EN_HC380LA | 440 | 380 | 480 | 19 | - | - | 0.1 | 1.6 | 0.05 | - | 0.025 | 0.025 | 0.15 | - | |

| EN_HC420LA | 470 | 420 | 520 | 17 | - | - | 0.1 | 0.71 | 0.05 | - | 0.025 | 0.025 | 0.15 | - | |

| C-Mn HIGH STRENGTH STEEL | JFS-JSC340W | 340 | 185 | 285 | 36 | - | - | 0.12 | 1.5 | 0.05 | 0.015 | 0.025 | 0.025 | - | - |

| JFS-JSC390W | 390 | 225 | 335 | 32 | - | - | 0.18 | 1.8 | 0.05 | 0.015 | 0.025 | 0.025 | - | - | |

| JFS-JSC440W | 440 | 265 | 370 | 29 | - | - | 0.22 | - | 0.05 | 0.015 | 0.025 | 0.025 | - | - | |

| JIS-s PFC490 | 490 | 295 | NA | 24 | - | - | 0.25 | - | 0.05 | 0.015 | 0.025 | - | - | - | |

| Rephosphorized | EN-HC180P | - | - | - | - | - | - | 0.05 | 0.6 | 0.08 | - | 0.025 | 0.08 | - | - |

| EN-HC220P | - | - | - | - | - | - | 0.07 | 0.7 | 0.08 | - | 0.025 | 0.08 | - | - | |

| EN-HC260P | - | - | - | - | - | - | 0.08 | 0.7 | 0.1 | - | 0.025 | 0.1 | - | - | |

| JFS-JSC440R | 440 | 335 | 440 | 26 | - | - | 0.1 | 1.5 | 0.5 | 0.15 | 0.025 | 0.12 | - | - | |

| JFS-JSC590R | 590 | 410 | 560 | 18 | - | - | 0.15 | 2 | 0.5 | 0.15 | 0.025 | 0.12 | - | - | |

| Dual Phase | EN-HCT500X | 500 | 300 | 380 | 23 | - | - | 0.14 | 2 | 0.8 | - | 0.025 | - | - | - |

| JFS-JSC590Y | 590 | 320 | 440 | 19 | - | - | - | - | - | - | - | - | - | - | |

| JFS-JSC780Y | 780 | 420 | 590 | 14 | - | - | - | - | - | - | - | - | - | - | |

| JFS-JSC980Y | 980 | 580 | 920 | 10 | - | - | - | - | - | - | - | - | - | - | |

| JFS -JSC980YL | 980 | 580 | 730 | 11 | - | - | - | - | - | - | - | - | - | - | |

Applications & Grades

- Automobile

- White Goods

- Cold Rolled Formed Sections

- Furniture

- Drums & Barrels

- Engineering & Fabrication